Home - Marine coating systems - Rudder and running gear protection

Rudder and running gear protection

Rudders, Kort nozzles, thruster tunnels and other running gear of a ship are particularly susceptible to the devastating damage that can be caused by cavitation and corrosion. This can result in deep pitting and sometimes complete failure, needing very expensive repairs or replacement. The problem has remained unsolved until now.

The high costs of rudder and running gear damage

When a ship comes into drydock, maintenance of its rudder and running gear can be expensive and time-consuming. Cavitation and corrosion damage repair often involves hot work, grinding and recoating. Thus a poorly protected and damaged rudder or other running gear can extend drydocking time and costs considerably.

The costs involved go far beyond simply repairing and recoating the damaged rudder. Drydock expenses and off-hire time add up quickly. And if underwater repairs are needed for these parts in between drydocking, further expense is incurred.

The cause of the trouble

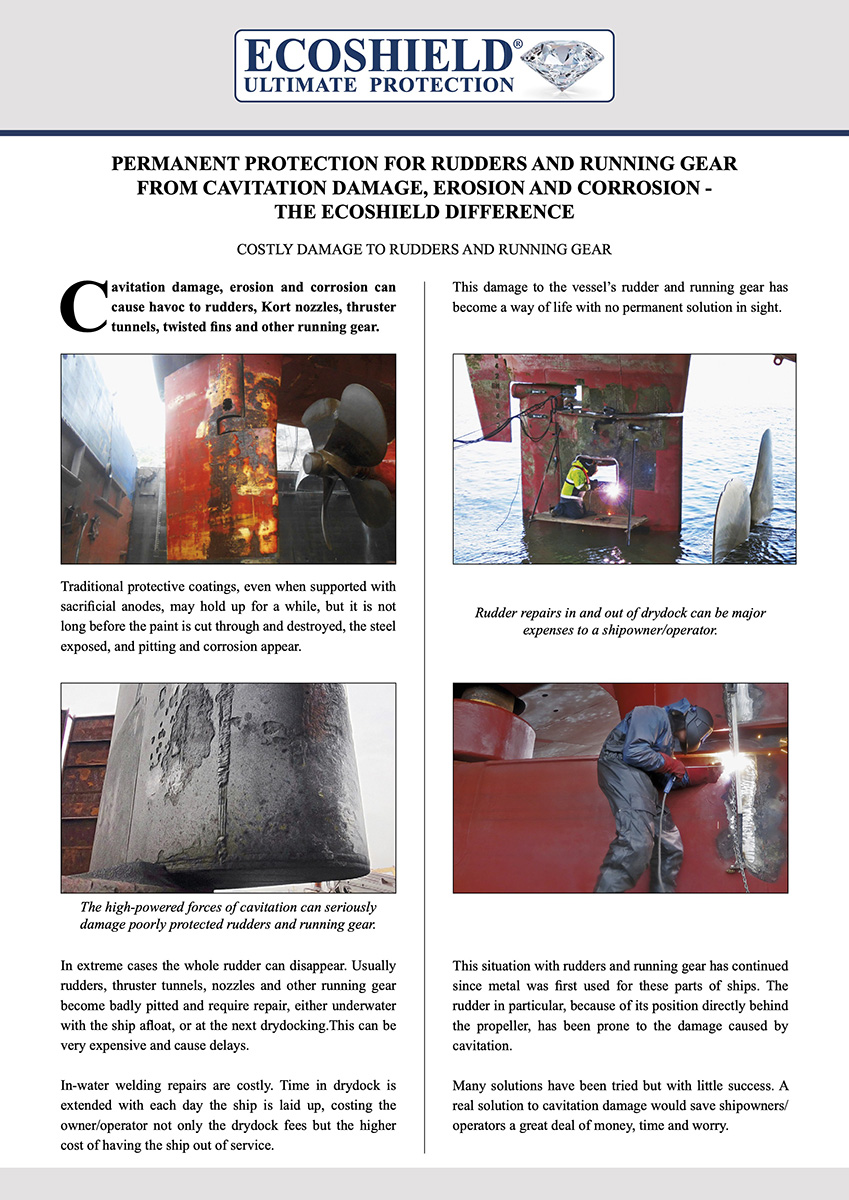

Hydrodynamic cavitation is a phenomenon that accompanies turbulent fluids. The motion of a propeller through the water, for example, results in small, vapor-filled cavities or bubbles.

The pressure around these cavities increases until they collapse suddenly. The implosion is accompanied by very high pressure pulses, speed and temperatures in the water.

These impact the rudder, the thruster tunnel, the nozzle and energy saving devices in particular.

The solution – Ecoshield

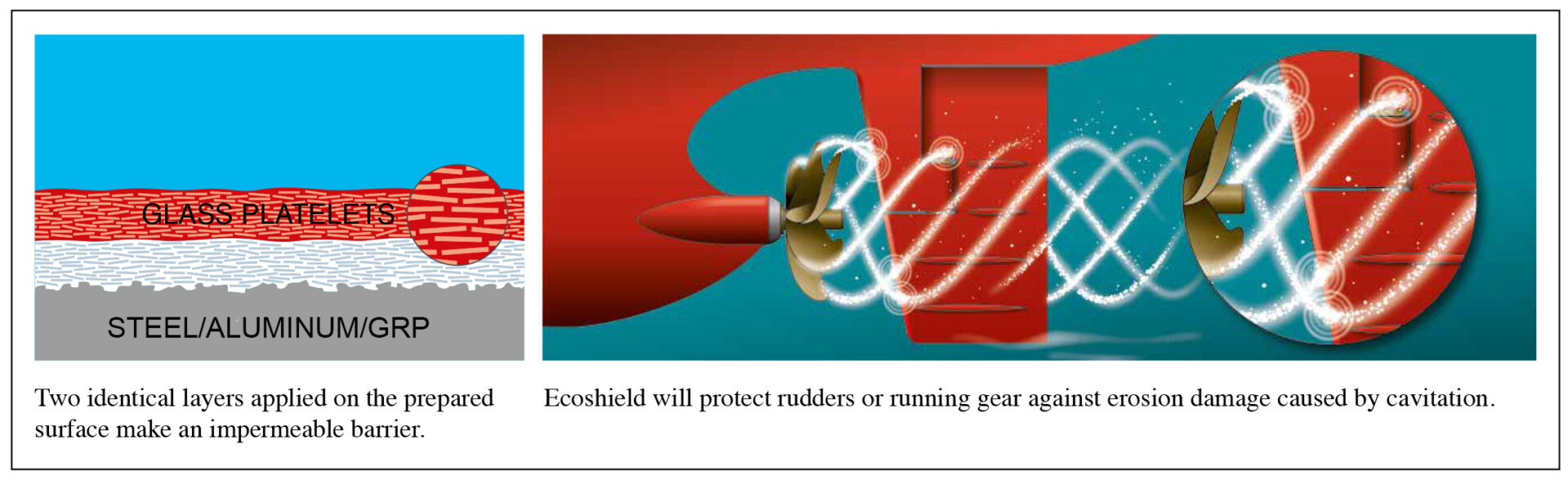

A thick vinyl ester base with a very high concentration of glass platelets forms the impenetrable barrier needed to resist the forces of cavitation and galvanic corrosion.

Applied at newbuild, it will provide lifetime protection. It can also be used to repair

and protect ships already in service with damaged rudders or running gear.

The Ecoshield difference

Key features

• Ideally applied at newbuild so rudder and other running gear remain in pristine condition for the life of the vessel. Easier to apply during construction, avoiding the time pressure of drydock.

• Can and should also be applied on rudders and running gear that are already in service at next drydocking.

• Stays on for the life of the vessel without need to repaint.

• If mechanical damage occurs (anchor chain or collision) the bonding is so strong that undercreep will not occur.

• At most, minor touch-ups will be required during routine drydocking.

• Surface must be grit-blasted to produce a profile of at least 75µm and SA 2 ½ cleanliness.

• Weld slots can be filled with Ecofix prior to Ecoshield application.

• Airless spray, single feed. Requires no special equipment or conditions.

Key features

• Ideally applied at newbuild so rudder and other running gear remain in pristine condition for the life of the vessel. Easier to apply during construction, avoiding the time pressure of drydock.

• Can and should also be applied on rudders and running gear that are already in service at next drydocking.

• Stays on for the life of the vessel without need to repaint.

• If mechanical damage occurs (anchor chain or collision) the bonding is so strong that undercreep will not occur.

• At most, minor touch-ups will be required during routine drydocking.

• Surface must be grit-blasted to produce a profile of at least 75µm and SA 2 ½ cleanliness.

• Weld slots can be filled with Ecofix prior to Ecoshield application.

• Airless spray, single feed. Requires no special equipment or conditions.

• Applied directly to prepared steel, no primer.

• Final DFT usually 1000µm but also 1500µm or 2000µm depending on requirements (500µm per coat with a 3-hour overcoat time).

• Rudder or other running gear already damaged and pitted can be filled with Ecofix, a compatible, permanent filler. Ecofix can replace welding repair in many cases.

• The Ecoshield bonds perfectly to the Ecofix as the basic chemistry is the same.

• The result is a new, indestructible surface for the steel, other metal or GRP.

• Ecoshield comes with a 10-year warranty.

Note: Only a rudder is shown in these illustrations but this applies equally to nozzles, twisted fins, and other running gear.

Contact us for more information or a quote for an upcoming project

Do you have a newbuild or docking coming up that you feel Ecoshield would be the perfect fit for? Contact us now and we will answer your questions and provide a quote for the project.

Download the Ecoshield Brochure

Complete details about Ecoshield, including all the parts of your ship that can be protected with this remarkable product.

References, technical materials and further information for download

There is a wealth of information on Ecoshield and our other products available in the form of books, white papers, case studies, magazine articles, technical guides, brochures and other literature.